CNC Parts Loader

Programming and operating CNC machines can be both engaging and rewarding. However, once a design is finalized and programs are proven, tasks like loading parts or performing inspections can become tedious—especially for short production cycles that don’t allow time to multitask. A fully automated system capable of loading raw material, handling multiple operations, inspecting parts in-process, and quickly adapting to new jobs would greatly improve efficiency for small-batch production.

Project Definition

The system needed to handle small-batch production runs completely autonomously while adhering to the lean principle of single-piece flow, where each cycle produces a finished part. Flexibility in accommodating various part sizes, shapes, and quantities was critical. Additionally, the system required built-in error detection and mistake-proofing to prevent issues such as input errors, mid-process defects, or hazardous conditions.

Project Design

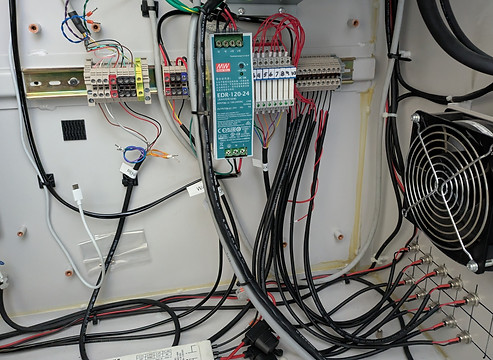

The design utilized a pneumatic system with a gripper mounted to a tool holder, allowing it to function like a standard tool for simplified programming. A relay bank controlled by auxiliary I/O from the CNC machine eliminated the need for external controllers, while a solenoid bank operated pneumatic devices, including vises, grippers, and rotary actuators for flipping parts. Renishaw probes were incorporated to locate, measure, and test parts and tools, providing comprehensive error-checking capabilities. Custom 3D printed components, such as a bypass air line and gripper adapter, allowed the pneumatic gripper to run through the tool changer without interfering with other tools.

Project Delivery

The system successfully actuated the spindle-mounted gripper, demonstrating its ability to load and manipulate materials. The 3D printed dovetailed jaws provided flexibility in adapting the gripper for different stock sizes.

This project is still in process... I am working on the integration of the pneumatic vises and "part flipping" actuators, so be sure to check back for future developments!